PGD in Supply Chain in Bangladesh

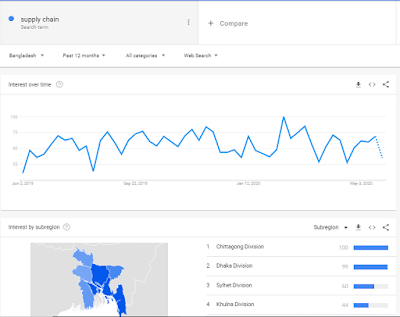

PGD in Supply Chain in Bangladesh Supply chain courses are the hyped courses in Bangladesh now. So many institutions are trying to provide the supply chain courses to cover a large number of graduates. Trend analysis shows that in Bangladesh within the 12 months the search supply chain was dramatically higher. It's top in the city of trade Chittagong. Let's have a look at the following image. Today we will share some institution names who conduct PGD courses in Supply Chain Management in Bangladesh. They are 1. Mind Mapper Bangladesh 2. DCCI Bangladesh 3. BIMS Bangladesh 4. Career Hub BD 5. BIHRM 6. BISCM 7. ABP These institutions are suggested by different professionals in our group Supply Chain Management Students of Bangladesh . So if you have any queries, please click the link and contact them for the course details. Don't forget to join our Facebook Group. Gazi Sanaul Hasan